| 070

|

A Cardboard Head-Protector for Edgar

Children with epilepsy (fits), who suddenly lose consciousness and fall,

often need a padded helmet or head protector to prevent head injuries.

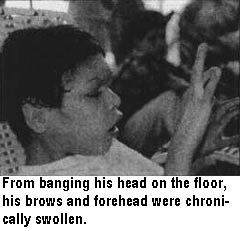

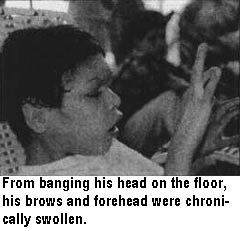

EDGAR, whose brain was damaged at birth, had been

brought repeatedly to PROJIMO from a distant village by his mother (see

Chapter 4). His condition had steadily

improved. But after his father was murdered, he developed a serious problem,

perhaps related to family stress. His mother lost her restaurant job. She

worked long hours away from home, selling odds and ends to keep her children

fed. She had little time for her disabled son. Sometimes Edgar's brothers

and sisters played with him after school. But for many hours a day, Edgar -

who could neither walk independently nor talk - sat in a corner or lay on a

mat, unattended.

Bored and lonely, the boy had developed harmful, self-stimulating

behaviors. He rocked back and forth, stared at his hands, hit his face with

his fists, and banged his head on the floor. His mother said he hit himself

to make himself cry, to get attention. The team suggested that she give him

more attention when he was not hitting himself, to reinforce his positive

rather than his harmful behavior. But they realized she was depressed,

overworked, and needed help. So they found neighbors and a village health

worker to take turns caring for Edgar, to provide him with human contact,

and to stimulate him with rewarding activities.

But patterns do not change overnight. Edgar needed some kind of head

protection. But the family's visit to PROJIMO was brief. In 2 hours, the bus

would leave for their distant village. So Mari and her helpers decided to

quickly improvise a simple cardboard head-protector. |

| 071

|

|

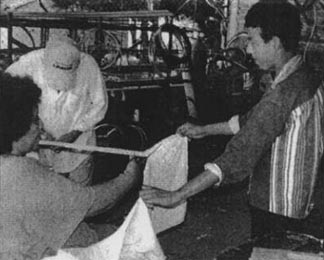

1. After measuring Edgar's head, Chon (who is deaf) helped Mari cut a

long strip of cardboard, with several "arms," to form a head-band with

criss-cross straps. |

2. To make the helmet fit, Mari and Chon used an old plaster leg-mold

which they rounded and filed to the size of the boy's head. |

|

3. Mari tried the unfinished helmet on Edgar for fit. To protect his

forehead more, the headband had to be lowered a little. |

4. After making a few adjustments, Chon and a young helper glued the

cardboard helmet together. To hold it in place, they sewed the layers of

cardboard together with string. |

|

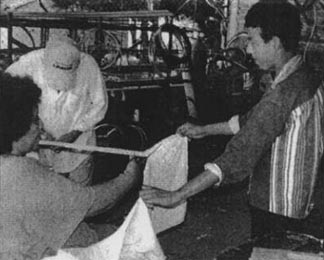

5. Martín helped Mari cut strips of a soft towel to be used as

padding for the helmet. |

6. Mari wrapped the cardboard head protector with the strips of soft

towel. |

|

7. Mari attached a chin strap of soft cloth to the head protector.

Here she and Edgar's mother tie it gently in place. |

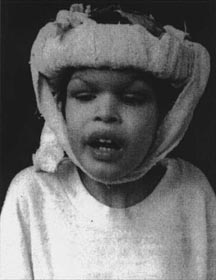

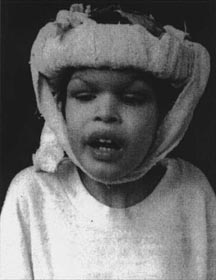

8. The new head protector was finished in two hours. The final steps

were hurried, and the glue was still moist. But Edgar's mother said she

would cover it more neatly with cloth padding at home. |

We hope that the cardboard helmet will help protect Edgar and prevent

further damage caused by his hitting his head.

Far more important, however, is the need for community support, loving

attention, warm physical contact, and playful, stimulating activities.

Fortunately, the community health worker in the village, who used to work at

PROJIMO, is very capable and conscientious. He has agreed to find a

warm-hearted local woman who works well with children, and who has the time

to care for Edgar for 3 or 4 hours a day. The health worker will provide

training and advice to Edgar's care-provider, so that Edgar gets the

rehabilitation and the developmental stimulation he needs.

|

| 072

|

Suggestions for Making an APT Specially Designed Seat

(adapted from a sheet prepared by Kennett and Jean Westmacott)

|

1.Plan the seat according to the child's needs and

possibilities. With the child's help (as much as is possible),

experiment to find a helpful sitting position. Try different placement,

angles, and amounts of support. (To do this, use chairs, hands, boxes,

sandbags, and wedges as needed.) Look for a position the child likes,

that provides good posture and encourages more self-control and use of

head, body, and hands. Sketch a seat design accordingly.

2.Measure the child. With the child in a sitting

position, take measurements for the height, depth, and width of the

seat, and the height of the seat-back (see

page 42).

|

|

3.Make several laminated (layered) cardboard flats.

For the sides, back, seat, armrests, and lapboard of the special chair,

cut corrugated cardboard sections from old cartons. Paste together 4 to

10 layers with the corrugation alternating (each layer criss-crossing

the one below). |

|

4.Pressure-dry. Put a flat board, with heavy

weights on it, on the cardboard until it drys completely and is hard.

(This may take several days.) |

|

5.Make cardboard tubes (for girders and struts).

Rub paste onto large sheets of thin, dense (not corrugated) cardboard

and roll it around a straight bamboo or broomstick. Pull off and

let dry. Make 8 or more tubes, depending on your design. (If

thin, solid cardboard is not available, cross-struts can be made by

cutting bars from a laminated section of corrugated cardboard.)

|

|

6.Cut holes in the chair-sides that

will fit tightly around the cross tubes. (For best alignment, place the

two chair-sides together and cut the holes in both sides at once.)

7.Assemble and check. Cut the sides, seat and back

flats to the correct size. Assemble, and make necessary adjustments. (If

possible, try sitting the child in the chair before gluing.) Let tubes

stick out a little. Slice tube ends lengthwise, bend strips over, and

paste them firmly to chair-sides with many thin layers of strong paper

strips. (Or rub tube-ends with a stone to flatten them. Torn edges stick

better than cut ones.) |

|

8. Turn chair over and paste "angle irons"

of dense cardboard bent at a right angle between seat and sides. |

|

9.Paste over all other edges with layers of thin,

strong paper. Finally, cover the whole chair with a finishing

layer of strong paper. (Cement bags, wall-paper, or pages from

old magazines work well.) Using paper with colorful pictures makes it

more fun! Decorate as sparks your fancy! 10. When

totally dry and hard - it may take a week or more - varnish to

seal. A plastic (polyurethane) varnish provides good, safe

protection. |

|

| 073

|

How PROJIMO's Cardboard Aids Differ from the APT Developed in

Zimbabwe

The methods used at PROJIMO for cardboard special seats and other

assistive devices have been adapted from those developed in Zimbabwe by

Bevill Packer and described in his fine book Appropriate Paper-Based

Technology (APT): A Manual. (For the full reference, see

Resource List 2, page 344.) The Zimbabwe

methodology, summarized on the facing page, has been modified somewhat to

meet the situation in rural Mexico in the following ways.

TYPES OF PAPER. The Zimbabwe APT seats use 4 main kinds

of paper, in different ways:

- Corrugated cardboard such as that used in cardboard

cartons. Laminated sections of this thick, light cardboard are often used

for the sides and backs of special seats.

- Extra-strong paper such as that used for cement bags.

Strips of this are used for edging, and for joining pieces of the frame

together. Pasted in place, it makes strong angle joints.

- Thin (solid) cardboard such as that used for shoe

boxes. This, and other strong, thick paper is mainly used to make

structural supports, often in the form of tubes (see facing

page).

- Ordinary newsprint, wrapping paper, and the like.

These are usually used by tearing the paper along its grain into thin

strips. In a criss-cross pattern these are pasted into layers, either upon

a flat surface, or over a form of the desired shape (paper-maché

technology).

In Mexican villages, only the first two kinds of paper are readily

available: corrugated cardboard cartons, and the

strong brown paper from old cement bags, building-plaster bags, and

corn flour (Maseca) sacks. Therefore, at PROJIMO, paper-based

devices are made almost entirely of corrugated cardboard and surfaced with

strong brown paper. Because of the air spaces within corrugated cardboard,

walls of assistive devices must be extra thick.

For support struts such as those that hold up the horizontal seat of a

Zimbabwe APT chair, you can use round tubes of thin cardboard. PROJIMO uses

rectangular "beams" made by laminating corrugated cardboard. These must be

extra thick to have enough strength.

PASTE. Zimbabwe APT recommends making a thin paste with

flour and water, as follows:

The Zimbabwe manual emphasizes that for gluing strips of paper or thin

cardboard, a very thin paste be used, so that it penetrates the

paper's surface. (Use of thick paste may later attract termites!) However,

when making flat boards by pasting together layers of corrugated cardboard,

it is essential to work fast and use very little paste. You must "Race the

stretch!" says the manual. If the cardboard gets too wet (from too much

paste or from working too slowly) the inner, wavy (corrugated) layers tend

to come loose or lose their shape. Drying time is also longer. To end up

with strong, flat, smooth boards, the laminated cardboard must be pressed on

a flat surface under a weighted plank until completely dry.

To glue together small cardboard structures, PROJIMO sometimes uses

carpenter's white glue instead of flour-and-water paste. It dries

faster and may be stronger but costs more.

CARDBOARD PLUS OTHER MATERIALS. While the Zimbabwe APT

Manual encourages using only paper products as building materials,

PROJIMO has experimented with combining paper with other low-cost and scrap

materials. For example, the special seat for Cruz has a few wood hooks and

pegs. Its narrow foot-bar consists of a scrap piece of metal bar (for

strength) covered with layers of corrugated cardboard (for padding). Cruz's

walker combines the use of cardboard and wood. Each material has advantages. |

| 074

|

PAPER-BASED TECHNOLOGY IS NOT JUST FOR POOR COUNTRIES:

Examples from England

Paper-based technology (APT) is not only appropriate for poor

countries. Its adaptability and versatility make it useful

anywhere. In England, Ken and Jean Westmacott run a workshop

called People Potential where they train families of

disabled children to design and create home-made assistive

devices. The examples below were made by Sigi Lester for her

daughter KIM who has Rett Syndrome, a profound

mental and physical disability. Sigi became so skilled at making

aids for her daughter that she now runs her own courses on APT,

teaching parents of disabled children. All her equipment is

beautifully decorated.

|

This swing seat was made from cardboard layers. A low

back-rest helps Kim gain better body control. Molded hollows

under her butt keep her from sliding forward and help her to

sit straighter. Sigi covered the seat with a non-slip

material to prevent Kim from slipping forward, and thus

improve her posture. |

Kim loves her APT car-seat because it is covered with

colorful old maps. The seat swings toward the van door for

easy access. |

This APT chair-insert with armrests enables Kim to use

the same furniture as the rest of the family, yet gives her

the extra support that she needs.

An anti-slip surface ensures good posture and safety. |

|

Kim's mother made this walker from rolled tubes of thin,

pasted cardboard. The A-frame gives just enough trunk

support so Kim can begin to take steps. Wheels made with

hard plastic-balls (toilet floats) strengthened with layers

of pasted paper, roll well on soft ground. |

Kim's mother had a "bad back," yet daily had to carry Kim

up and down many stairs. She made this APT carrying-seat

molded to fit against her own hips and back. She got the

idea from the way Sherpas in Nepal carry people (see

p.143). The seat is decorated

with golden stars and a moon on a dark blue background. |

|

|