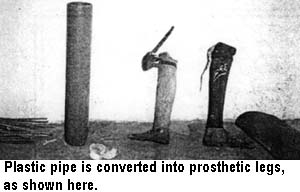

A Mukti Limb - Made from Plastic Pipe

The Jaipur foot is not the only user-centered breakthrough in prosthetic

limbs from India. In 1986, Meena Dadha, a remarkable woman from Madras,

became concerned that there were hundreds of thousands of amputees in India

who needed a limb and could lead more fruitful, happier lives if they had

one. A method of leg-making was needed where limb-making teams could "go to

the people," even in remote villages, and make good quality legs quickly at

low cost.

Mukti is the name of a limb-making program that has its main base in

Madras, and runs a mobile outreach program to rural areas. The limb-making

equipment is transported in a van to small towns that invite Mukti's service

and agree to bring together amputees from nearby villages. A 5 or 6 day

workshop is organized in a temple, meeting hall, or school.

As part of a United Nations training program, I (the author) had the

privilege of observing a Mukti workshop in a remote village. To my

amazement, a team of 5 craftspersons produced 60 limbs in 5 days. I watched

as they made a limb for a poor farm worker. He began to walk on his new limb

just 2 hours after the first measurements were taken! (He, of course, stayed

longer for gait training and adjustments.)

The key to this fast, low-cost technology is the use of plastic water

pipe for the socket and the shank of the limb. The pipe is 3 inch diameter "HDPE"

(high density polyethylene) irrigation pipe, with a melting point of 134 to

137 degrees C. It is produced by Polylefins Industries, which makes

skin-colored pipe especially for Mukti. (The pipe is somewhat different from

PVC pipe, and easier to mold.)

To make the limb, a plaster mold of the stump is made. To the bottom of

this mold, plaster of Paris is added to form a mold of the entire shank. To

do this, a cardboard cone is attached to the bottom of the stump mold, and

filled with plaster-of-Paris (see drawings on next pages). A measured

section of plastic pipe is put over a stout wooden stick, and is heated in

an oven until it begins to droop.

Then, the hot pipe is stretched over the cast of the leg.

On cooling, the plaster is removed from the inside of the mold. A

pre-made rubber foot, similar to a Jaipur foot (produced in different sizes

in Mukti's center in Madras), is fixed to the bottom of the shank. Straps

are attached to the top of the limb to hold it firmly on the stump.

The results are impressive. The elderly farm worker whom I saw fitted was

able to walk surprisingly well with his new, light-weight leg on that same

afternoon. He was overjoyed.

A series of drawings on how to make the limb, from a booklet by Mukti,

are reproduced on the next 3 pages. |